Furkey custom machining and castings service is the process of manufacturing metal components specifically according to customer requirements, such as drawings, material requirements, and mechanical properties. We can choose the right process and craft unique molds based on client needs.

In the process of receiving custom casting services, customers often face concerns ranging from process selection, mold design, sample testing, to mass production and international transportation. We understand your concerns, hence we provide an all-in-one service. From understanding your requirements to final delivery, we’ll guide you every step of the way, ensuring a smooth and worry-free journey through your custom casting experience.

Based on the annual usage and mechanical characteristics of the castings, select the most cost-effective casting process for customers and provide detailed quotations. Custom metal casting molds, start mold development after confirming the process and quotation to ensure accurate manufacturing of parts. Make sure to choose the best mold material to ensure its longevity. Develop production plans according to customer delivery requirements to meet customer needs to the greatest extent.

Usually before mass production, the foundry will mail samples for testing to ensure that the casting quality meets customer expectations. Conduct various tests, including but not limited to material testing, coordinate measurement, X-ray testing, magnetic particle inspection and sampling testing to ensure parts meet high standards. Provide comprehensive test reports to ensure transparency and credibility of the partnership, such as CNAS reports.

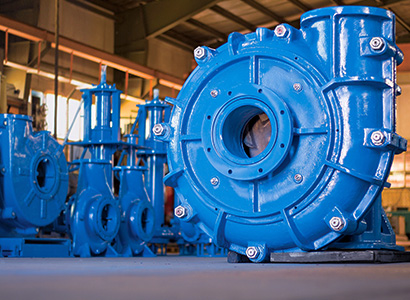

The parts produced by investment casting have extremely high surface finish and are suitable for producing parts with complex shapes; Sand casting is a casting process for large parts, and the parts produced The surface is slightly rough; Vacuum casting is a unique process that can reduce the content of gases and impurities, which is beneficial to improving the surface finish of the casting; Die casting is a high-pressure casting process that uses high pressure to quickly inject molten liquid metal into a mold to create high-precision parts. High-pressure injection molding can greatly improve the surface finish of parts, and can ensure the smoothness of parts with extremely complex shapes. This process is suitable for producing automobile frames and casings for electronic equipment. Centrifugal casting is a casting process specifically for hollow tubular parts. The casting method of this process is very special. It uses centrifugal force to uniformly solidify the liquid metal in the mold while the mold is rotating at high speed. The hollow parts cast by this process have uniform density and high precision. Usually used to cast pipes or wheel hubs with superior performance.

Each process has its unique advantages and scope of application. In the process of providing customized casting services to customers, engineers will select the appropriate process for the customer based on the customer’s demand for output and the application scenario of the parts, while ensuring product quality. Under the premise of planning the most cost-effective production plan for customers.

For different materials, such as custom aluminum castings; custom brass castings; custom stainless steel casting and so on, custom casting service will select suitable materials for customers based on product performance. Let’s explore together and find out which casting process is tailor-made for your industry!

Machining is a manufacturing process that involves cutting, shaping, machining, and finishing workpieces using mechanical equipment such as machine tools. This process is typically used for precision machining of metals, plastics, and other materials to produce parts, components, and products to meet specific engineering requirements. Machining operations can include drilling, milling, turning, grinding, threading, and more to achieve the desired shapes, dimensions, and surface qualities.

Furkey Machining Factory is a leading example of expertise in machining. With state-of-the-art machinery and skilled professionals, Furkey specializes in providing high-quality machining services for various industries.

CNC Machining Service:

Explore the perfect CNC machining solution for your metal component needs, delivered precisely when you need it. Trust our team of experts to seamlessly guide your project from the initial design and prototyping phases to full-scale production. At Furkey, we transform your vision into metal reality.

At Furkey Machining Factory, precision is paramount. We utilize cutting-edge Coordinate Measuring Machines (CMM) for meticulous 3D inspections. These advanced tools ensure every component meets tight tolerances.